We manufacture batching plant chillers for concrete plant which provide customized operation of concrete mixing along with the cooling application.

Our RMC chiller (Cement chiller) also called batching plant chiller is environment friendly and can be easily installed (and reused at different sites after completion of the job) in any requirement according to the client. All the equipment is properly tested in international parameters to offer the best possible functionalities. Our RMC chiller specifically design with simplicity to reduce the cost. It will ensure to have 4 degree Celsius and chilled water temperature along with the proper process requirement.

Batching Plant Chiller

Batching Plant Chiller:

Batching plant chiller for concrete plants are specifically designed to operate in a dusty batching site even within extreme weather conditions. It can properly work under the sun and rain and in all the harshest environments possible.

All the major components in the refrigeration circuit are selected in design according to the condition and utilization of the available site. The complete study for the batching process requirement is needed to process the choice of equipment and accessories. The engineering team will have the specific expertise in the batching plant chillers which will offer the best possible option for the industry. The clients can procure Batching Plant Chiller specifically made for extreme tropical weather conditions which will maintain the operation and energy efficiency at a very affordable price.

For concrete applications, the thermal load capacity is the single most determining factor in chiller buying decision. Air cooled chillers are normally installed for concrete cooling applications because of their ease of installation, however water-cooled chillers are energy efficient and hence the choice for others too. Typically, concrete is mixed into a batch that requires a particular amount of chilled water mixed in to cool the solution down after production. The chilled water provides strength to concrete which is ultimately used in the construction of metros, buildings, and other infrastructure.

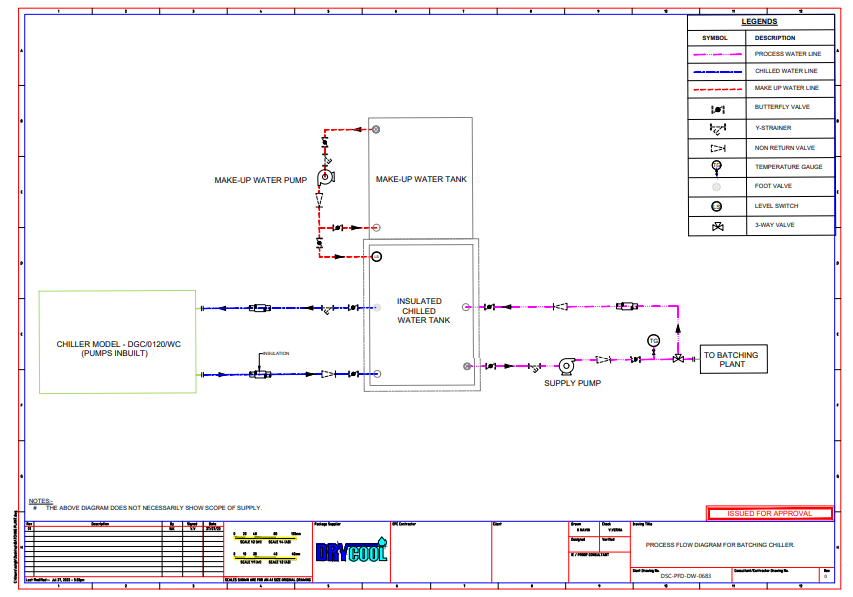

For Batching chillers, Drycool Design Engineers use complex algorithms to model the heat load using various inputs such as coarse aggregate, sand aggregate, amount of cement, quantity of water, inlet temperature of water and outlet temperature of water to calculate the sensible heat and the latent heat to be removed. Once, the batching chiller’s capacity is confirmed, the makeup water tanks and insulated chilled water tanks capacity are engineered and eventually the system is manufactured.

RMC (CEMENT) CHILLERS:

Our Batching Plant Chiller for concrete plant is properly manufactured and designed by our engineers.

Typically concrete is mixed into a batch that requires a particular amount of chilled water mixed in to cool the solution down after production. Batch Cooling is the majority of the applications related to concrete and cement cooling. DRYCOOL Chillers can be used to provide Chilled Water for concrete.

This is the main reason for the Batching Plant Chiller to have a low cost of ownership with proper and high design standards. We are having unique optimized compressor parts which are specifically designed for chilled water applications which will optimize the part-load efficiency and full load efficiency. The integrated microprocessor will offer high reliability by providing a proactive control strategy, easy interface, safety functions, simple diagnostics, etc.

Prominent Features of Drycool System’s Batching Plant Chillers:

Various features are integrated into the Batching Plant Chillers which we have listed below.

- Equipped with environment-friendly refrigerants R-404A and R-134A

- It is completely energy-efficient and reliable and equipped with a scroll compressor of European origin.

- It is equipped with a large-sized ice water storage assembly along with powerful water pumps.

- The electronic expansion valve is for large capacities, precise temperature control, and energy efficiency.

- High energy efficiency.

- Also get high condensing and low FPI count, which will offer coated fins. This will ensure easy maintenance and long life.

- Solution energy-saving equipment.

- Superior reliability.

- A fully automatic PLC-based unit is added for data login and remote operation facilities.

- Long equipment life.

- Specially designed for the lowest possible temperatures of water even without or with a reservoir.

- Adaptive frequency drive option available.

- Clean energy and intelligent management.

- Highly durable design with the best class cop.

- Efficient lubrication even during the power failure.

- Easy interface with BMS through protocols.

- Ozone friendly refrigerant HFC407c & HFC134a.

- The complete body is made out of galvanized steel.

- Polyurethane paint and powder coated.

- It is having a monocoque skid-mounted design for high reliability and extra ruggedness for proper mobile operation.

- Factory manufacture and tested tube in tube system along with shell and tube evaporators. It will offer a high flow high-pressure design along with various specific process applications. It is specially designed for handling suspended particles and fluid debris properly.

- Specially designed to produce ice water within the extreme conditions of 52 degrees Celsius.

- It is having high condensing areas and low if count which will increase the high flow and low noise with pressure control axial fans. It will offer the best energy efficiency while operating in harsh ambient conditions.

- Having fully automatic and step capacity control with multiple compressor operations ranging from 25 % to 100%.

- It will offer turnkey solutions that will provide ice water into the mixing area

- It is equipped with an advanced microprocessor-based controller.

- World-class safety controllers for compressors and equipment.

- Water flow switches and antifreeze safety.

- Completely functionally tested.

- Having dust and weatherproof qualities with IP 55 and IP 65 level protection.

- Custom-built machine inquiries are also being entertained due to specific requirements of the client.

- Site support along with AMC options for the entire life of the equipment.

- Get extended warranty options which are available for up to 5 years.

Advantages of Drycool System’s Batching Plant Chillers:

- The batching plant chiller is a completely construction-friendly machine that will help in saving money for the builder. It will reduce the labor cost and even the concrete can be made according to the need and availability of the raw materials. It will make a concrete mixture within a few minutes to work with the proper chilling procedure.

- The batching plant chiller can make fresh concrete anytime it is required for the industry. It will offer the same quality of concrete in every batch according to the proper engineering equipment. Easily add all the required amounts of the mixture to have desired concrete outcome.

- Batching plant chiller will ensure to make a mixture according to the right amount without compromising the quality and it reduces the chance of making any wastage during the process.