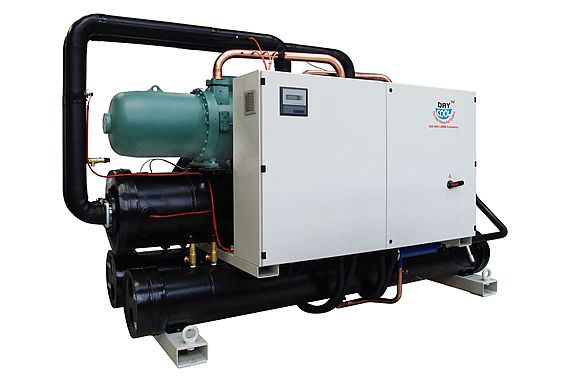

We Manufacture and supply HDPE pipes chiller, CPVC Pipes chillers, UPVC Pipes chillers. In the HDPE, CPVC, UPVC pipe industry, it has been observed that due to the high presence of dust content and suspended particles in the shell and tube evaporators of conventional chillers, choking is prevalent. This leads to severe damage in the chiller system and interferes with the production capacity.

Chiller for HDPE Pipes CPVC Pipes UPVC Pipes

-

However, Drycool Extrusion Chillers for HDPE Pipes, CPVC Pipes, UPVC Pipes ensure Durability, energy efficiency, maintains mold temperature, reduces scrap count and pipe manufactures can get high-quality PVC/CPVC & HDPE pipes. Drycool’s HDPE Chillers, CPVC Chillers and UPVC chillers can implement highly accurate precision control cooling process needed for extreme cooling of pipes. Our energy-efficient chillers circulate the coolant in the process, transfer the heat and produce strong and long-lasting pipes. Drycool extrusion chillers are reliable and provide efficient cooling for producing non-metallic pipes. Our versatile range of chillers delivers a wide choice of cooling capacities. Drycool offers various capacity of water cooled and Air-cooled chiller (ranging from 30 TR TO 900 TR) for HDPE, PVC pipes industries, with more than 500+ installations globally in the associated fields.

Whether it is pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings or wire insulation, plastic extrusion processes require chilled water from robust, highly efficient, and precise temperature control chillers to function correctly.

Plastic pipes are used for drainage systems, HVAC Systems, drip irrigation systems and other industrial processes. They also find wide applications in water distribution and low-pressure natural gas services. Features such as corrosion resistance, insulation and high strength gives them an advantage over conventional metallic pipes.The most used non-metallic piping materials in industrial processes include:

• HDPE (High-Density Polyethylene)

• CPVC (Chlorinated Polyvinyl Chloride)

• PVC (Polyvinyl chloride) -

The most used non-metallic piping materials in industrial processes include:

• HDPE (High-Density Polyethylene)

• CPVC (Chlorinated Polyvinyl Chloride) —higher strength at 200 deg C temperature than PVC

• PVC (Polyvinyl chloride)

CPVC Pipes, PVC pipes and HDPE pipes are produced by through the following extrusion process:

• Raw materials in powder or pellet form are added into a hopper.

• Through the hopper the raw material is gradually fed into the barrel of a single or twin-screw extruder.

• Powder or pellets melt when they are heated to nearly 200 deg C within the barrel.

• Continuous plastic tube or cylinder is formed when the extruder pushes the melted plastic through an annular die.

• Continuous plastic tubing is now cooled and extracted from the extruder. (Drycool’s extrusion chillers integrate process cooling to draw away heat from pipes during production. They ensure that the required temperature conditions are available for manufacturing the specific type of HDPE Pipe/ UPVC Pipe/ CPVC Pipe.)

• Within the cutting unit it is cut to the desired length.

• The product finally then enters a vacuum or pressure calibration, where it expands to its actual production size.

HDPE Pipes Chiller

CPVC Pipes Chiller

UPVC Pipes Chiller