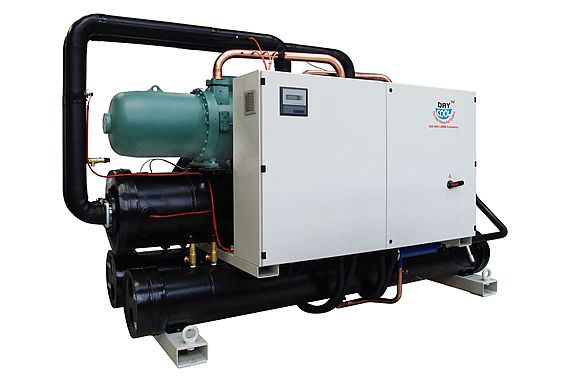

Inverter Screw Chiller

Inverter Screw Chiller:

We have introduced the new series of compressors in our inverter screw chiller, we just have an invalid inverter along with a permanent magnet motor in the bigger motor. Get the completely integrated three-step oil separator along with automatic two-step VI sliders. Other features include an oil filter, integrated check valve, and inbuilt MODBUS communication.

It is also has improved efficiency ranging between 5% to 70% compared to any other standard screw compressor. Get integrated part-load efficiency in the air-cooled inverter screw chillers. Water-cooled inverter screw chillers are having similar functionalities and integration of equipment. The only difference between them is the compressor which is being used for the cooling system.

We are offering the first screw chillers in India, as they are having more efficiency than a three-star chiller program. Get the advanced functionality of saving on power consumption which will be a great way to have a high return on investment. Every product we manufacture is made by maintaining international standards.

We are offering a wide range of capacities for every product of chillers. Every chiller will have the ability to handle a varied range of cooling requirements. Every chiller is having a combination of fixed speed compressor configuration along with the inverter to offer you the best possible outcome. Our wide range of products is perfect for offering air conditioning spaces such as hospitals, offices, hotels, and industries. It will help in maintaining the large fluctuations of load throughout the day in different seasons.

Effective Features of Inverter Screw Chillers:

These are the major effective features that will be offered with every inverter screw chillers.

- The screw chillers are completely based on external VFD which will have the ability to change the speed of the screw compressors. They can easily manage the speed of screw compressors between 40 Hz to 60 Hz. Which can be roughly converted into the range between 2200 RPM to 3500 RPM. Due to the integration of the inverter, the variable speed of the chiller can be easily changed between the range of 1750 RPM to 8000 RPM. This will give them better control over the speed which makes it the most important functionality of saving the power in both lower load and part load.

- None of the standard screw chillers will have the functionality to use at a lower speed but the inverter functionality to use at a lower speed but the inverter variable will give complete control on the speed. This is happening because there are no oil pumps at the lower speed in the standard chiller. Get the highly intelligent monitoring and software system that will maintain the levels and speed. It will also use the automatic process to keep the system running and healthy.

- The majority of the motors used in the inverter-based speed chiller is having a permanent magnet motor instead of a standard motor. This is one of the major advantages of having the part-load efficiency in every chiller.

- We are using the industrial standard of innovative design which is having integrated inverter compressor technology.